Production / R&D

THE PROJECT

JAMAŞ products are designed, manufactured, and tested in compliance with a number of international standards

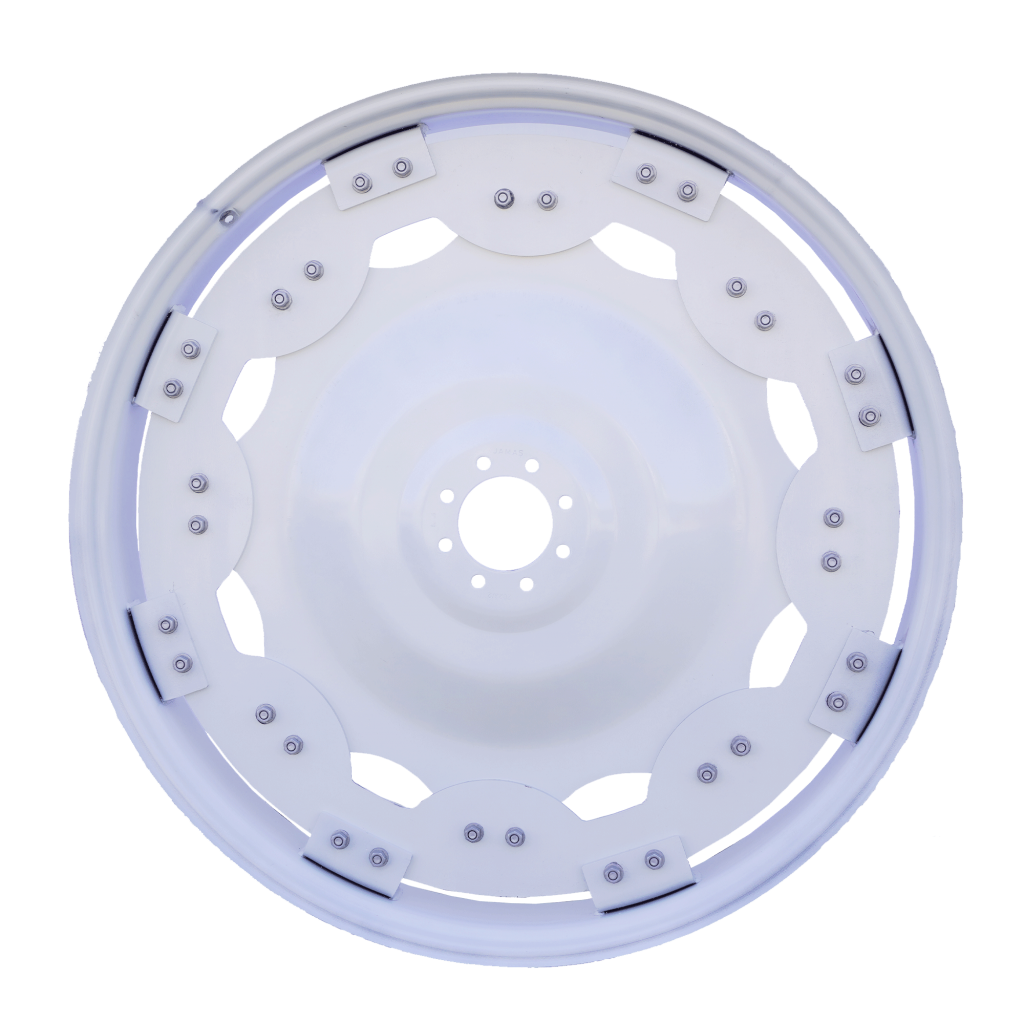

VISUALISATION

We can design and produce wheels in line with the special demands of customers based on years of experience. With the cataphoretic painting line, corrosion resistance and paint quality of products has been maximized.

RAW MATERIAL

Quality of raw materials has a major impact on safety of steel wheels. For every key component we cooperate with the globally leading suppliers, specialized in materials for wheel manufacturing

STEEL PREPARATION

We have ready stock for steel in our own warehouse in Diyarbarkır, where we cut the material to the appropriate size in preparation for further processing during production.

STAMPING DISCS

Our factory cuts and stamps wheel discs.

WELDING OF COMPONENTS

Steel wheels, discs and bare rims are welded by ourselves in factory. Thanks to them, we can sustain the highest level of repeatability of our wheels.

SURFACE PROTECTION

The welded wheels are passed to the paint shop. Here, first of all, we secure their surface using modern and ecological solutions – nanoceramics and cataphoresis. This combination guarantees high corrosion resistance and excellent surface preparation for painting.

POWDER PAINTING

The wheels are powder coated on our automated painting line. We offer clients a full range of RAL colours, including special colours.

TESTS AND TRIALS

We have implemented a quality management system that supports constant improvement of the entire organization. With this approach, we make sure that our worldwide customers benefit from the superior durability, reliability, and performance of our products and services.